Not known Details About Additive Manufacturing s

Wiki Article

5 Easy Facts About Additive Manufacturing Shown

Table of ContentsSome Known Factual Statements About Additive Manufacturing Oem Fundamentals ExplainedThe Buzz on Plastic ManufacturingThe smart Trick of Die Casting That Nobody is DiscussingThe Best Guide To MfgLean Manufacturing Can Be Fun For Everyone

The message on this page is a sample from our complete White Paper 'Injection Moulding for Buyers' - * Example text * - for complete overview click the download button above! Introduction This overview is meant for people who are wanting to resource plastic mouldings. It provides a much required understanding into all that is included with producing plastic components, from the mould tool needed to the moulding process itself.If you desire to discover additionally, the overview covers types of mould devices, along with unique completing procedures such as colours & plating. Words that are underlined can be located in the reference in the appendix ... Component I: Moulding: The Fundamentals The Advantages of Shot Moulding Plastic injection moulding is an extremely exact process that offers a number of advantages over other plastic processing techniques.

Accuracy is ideal for really intricate components. You can hold this moulding in the hand of your hand and it has employers, ribs, steel inserts, side cores and also holes, made with a gliding closed off feature in the mould device.

Everything about Manufacturing

from product feed & melting; product injection; cooling time and ejection to the re-closing of the mould tool all set for the following cycle. Draft angles - The walls of a moulded part ought to be slightly tapered in the instructions in which the part is expelled from the mould tool, to permit the component to be ejected conveniently.

Ejector stroke - The pressing out of ejector pins to eject the moulded part from the mould tool. Ejector stroke speed, size and also timing needs to be carefully regulated to stop damages to the ejectors as well as mould tool, yet at the same time make the moulding cycle as short as feasible.

Not known Facts About Manufacturing

Ribs - When a plastic recommended you read part has thin walls, ribs are contributed to the style to make the slim wall surfaces stronger Side cores - Side action which produces a feature on a moulded component, at an opposing angle to the normal opening direction of the mould tool. oem. The side core requires to be able to pull back as the plastic component can not be expelled or else.

Walls - The sides of a moulded part The message on this web page is a sample from our full White Paper 'Shot Moulding for Buyers'.

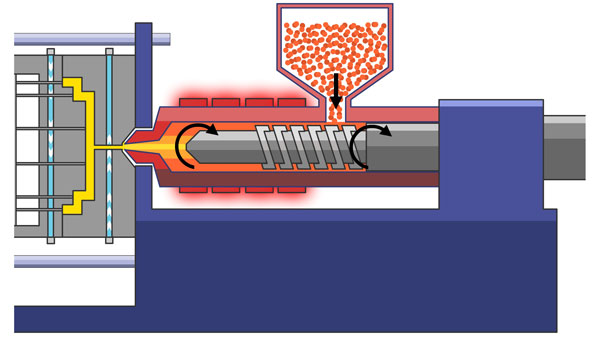

Injection moulding is widely made use of for making samsung foundry a selection of parts, from the smallest elements to whole body panels of cars and trucks. Injection moulding makes use of a special-purpose maker that has 3 parts: the shot unit, the mould as well as the clamp.

3 Simple Techniques For Die Casting

Process qualities [modify] Injection moulding makes use of a ram or screw-type bettor to compel molten plastic or rubber product right into a mould dental caries; this solidifies right into a shape that has adapted the shape of the mould. It is most commonly made use of to process both polycarbonate as well as thermosetting polymers, with the volume use the previous being considerably higher.: 13 Thermoplastics are widespread due to attributes that make them extremely suitable for shot moulding, such as ease of recycling, adaptability for a variety of applications,: 89 and also capacity to soften as well as move on heating.In multiple cavity moulds, each cavity can be the same and also develop the exact same components or can be distinct and create numerous different geometries throughout a solitary cycle. Moulds are usually made from device steels, however stainless steels and also aluminium moulds are appropriate for specific applications. Aluminium moulds are generally improper for high volume manufacturing or get rid of my review here slim dimensional resistances, as they have inferior mechanical residential properties and also are much more vulnerable to put on, damage, and also deformation throughout the injection and also clamping cycles; nonetheless, aluminium moulds are cost-efficient in low-volume applications, as mould construction prices and time are substantially decreased.

When enough material has actually gathered, the product is required at high pressure as well as velocity right into the component forming tooth cavity. The specific quantity of shrinking is a feature of the material being made use of, and also can be fairly predictable. To avoid spikes in stress, the process normally makes use of a transfer placement corresponding to a 9598% complete dental caries where the screw changes from a consistent speed to a constant stress control.

Hon Hai Precision Fundamentals Explained

Once the screw gets to the transfer placement the packing stress is used, which finishes mould dental filling and makes up for thermal shrinking, which is fairly high for thermoplastics relative to lots of other materials. The packing stress is used until the entrance (tooth cavity entrance) solidifies. Due to its little dimension, eviction is generally the first place to solidify via its entire thickness.: 16 Once eviction strengthens, say goodbye to material can enter the dental caries; accordingly, the screw reciprocates and also gets product for the next cycle while the material within the mould cools down to ensure that it can be expelled and also be dimensionally secure.Report this wiki page